Electrospinning

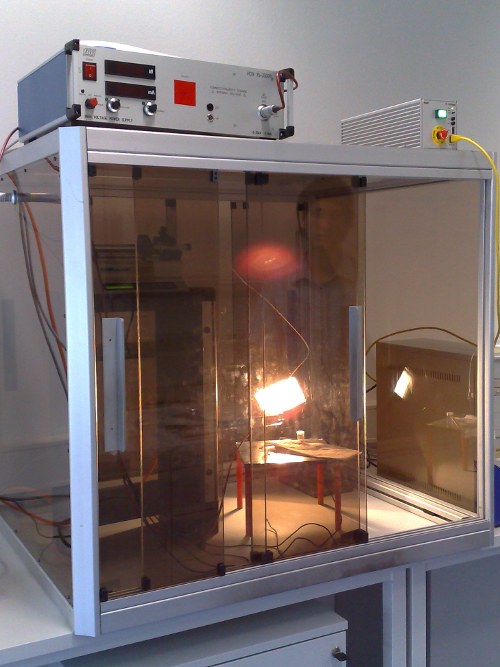

Inorganic, organic or composite nanofibres can be produced in 3 custom-built Electrospinning systems from precursor/polymer solutions. Expertise in coaxial nanofibres resulting in either hollow or core-shell systems as well as inert electrispinning opens the way to new applications for these anisotropic fiber meshes.

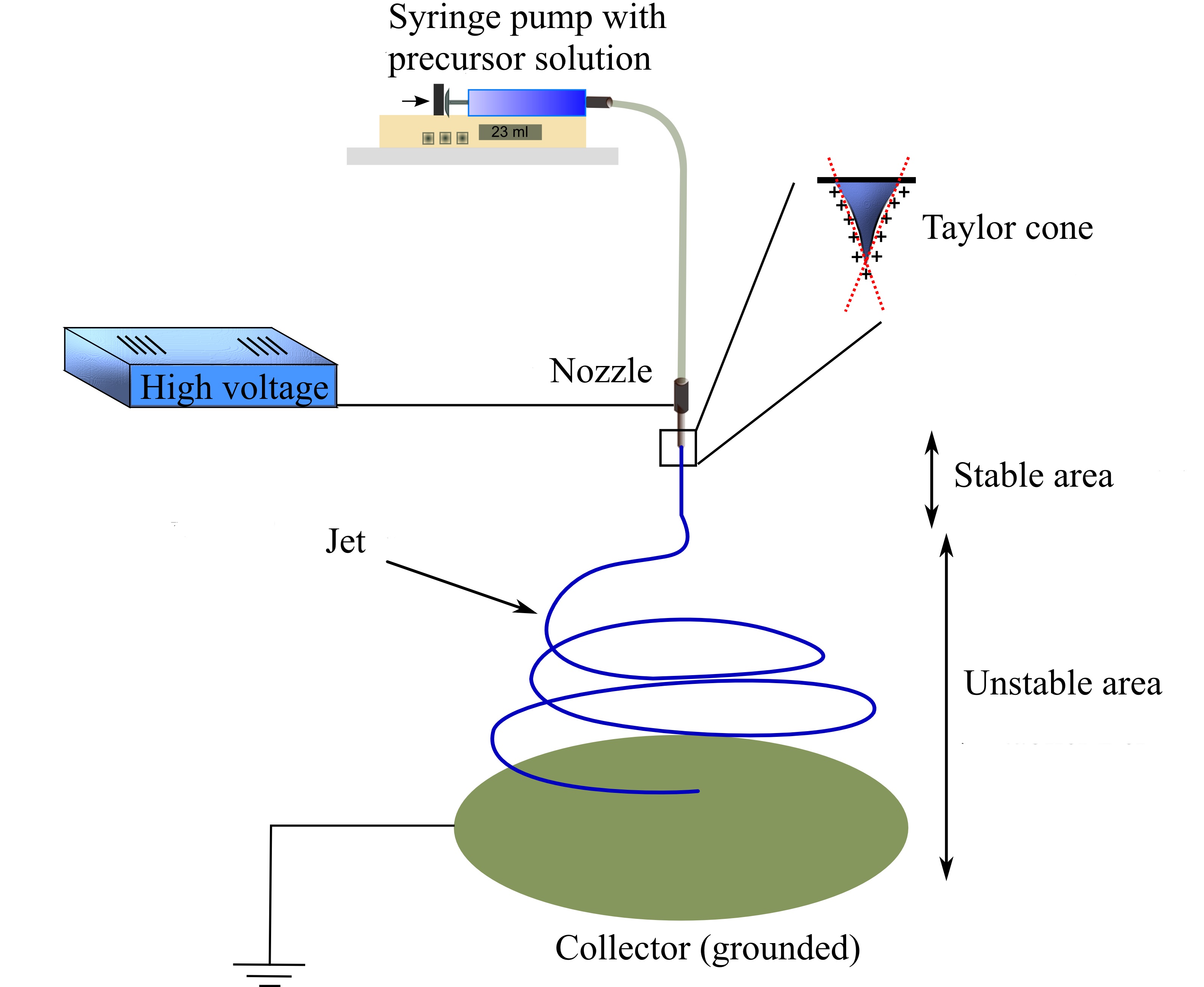

The electrospinning setup is really simple: it consists of a syringe pump which pushes the spinning solution out of a nozzle placed over a collector. Between those two a voltage of 10 to 25 kV is applied by using a high voltage source. Charging of the droplet at the tip of the nozzle leads to the formation of the so called Taylor cone. At the moment that electrostatic charge overcomes the surface tension a stable jet is released. In some distance from the nozzle the jet becomes unstable due to capillary forces caused by the evaporation of the solvent which means that the fibers start to bend and to split into multiple smaller strands with diameters in the nanoscale to form a flexible mat of continuous fibers on the collector .

A typical precursor solution consists of a polar solvent with a low boiling point, a polymer (which after the spinning process can be removed via calcination) and a source for the desired material (e.g. metal alkoxides, soluble salts).

In order to change the fiber morphology three groups of parameters can be varied concerning solution, environment and system. Solution parameters could be concentration, viscosity, conductivity, surface tension or permittivity, while environmental parameters include pressure, temperature, humidity, light, atmosphere constitution. Systematic parameters are voltage, distance between nozzle and collector, properties of the nozzle, pumping speed of the syringe pump, electrostatic field and the type of collector.

Electrospun fibers can be used as battery electrodes due to their self-supported structures and their large surface area. Other uses lie e. g. in the fields of transparent conductive layers (TCLs), photoelectrochemical (PEC) applications or in the medical sciences with the time dependent release of incorporated drugs or anti-bacterial particles from biopolymers.

Related to the electrospinning method is also the electrospraying. In this technique a particle solution without a polymer is released in the same setup. This time small particle containing charged droplets form instead of a constant jet. As the solvent evaporates, the charge is transferred to the particles which are finally due to like charges repelled from each other.