Photoelectrochemical Water Splitting

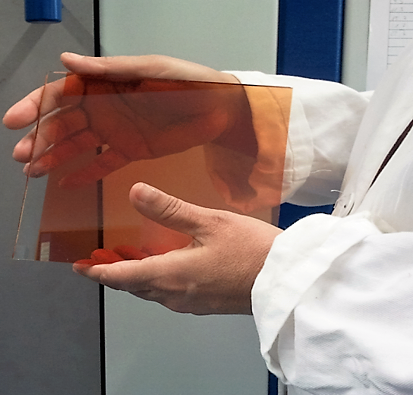

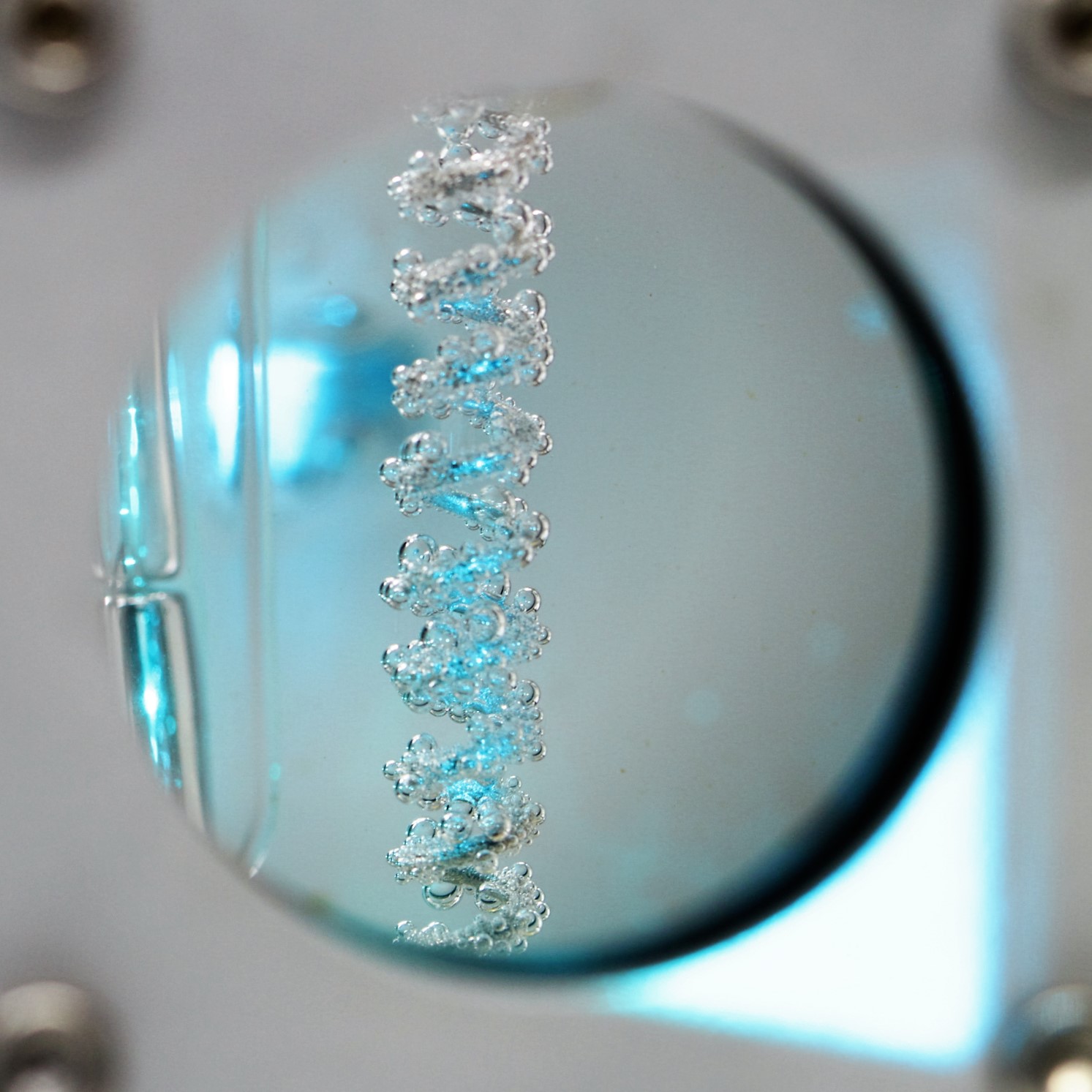

Due to growing interests of development in renewable/sustainable energy, hydrogen has been regarded as one of the alternative energy sources in research fields. Thanks to an earlier investigation by Fujishima and Honda (1972), a concept of photoelectrochemical (PEC) water splitting has been established, which utilizes the most promising solar energy to activate target materials and prevents emission of greenhouse gases as by-products. A fundamental PEC cell includes three electrodes system; a working electrode (n- or p-type), a counter electrode (e.g. Pt) and a reference electrode. Upon illumination of sunlight having energy equal or higher than energy band gap (Eg) of a material, photo-carriers (electrons and holes) are generated in the material and separated to participate in redox reaction of water. For example, in case of a n-type material, the holes react with water molecules at the interface of semiconductor/electrolyte and the electrons transferred through an external wire to reduce H+ to H2 at the counter electrode. On the contrary, H2 and O2 are evolved on a material’s surface and on a counter electrode, respectively, in case of a p-type photoelectrode. There have been numerous studies in this field to improve an efficiency of the system by either modifying candidate materials or seeking to new materials. Inorganic semiconducting materials like oxides, sulfides, and nitrides, etc. are of interest as photoelectrodes due to their properties which meet requirements for PEC water splitting system; i) band gap in the range of 1.8-2.2 eV to absorb sufficient solar spectrum, ii) efficient separation of photogenerated charge carriers to prevent recombination, iii) proper band alignment with respect to redox potential of water, and iv) sufficient chemical and photo stability in wide range of pH. In our group, active studies from syntheses of inorganic precursors to fabrication (and modification) of photoelectrodes for the PEC water splitting application using both gas phase deposition (CVD, PECVD) and liquid phase deposition (spray pyrolysis, doctor blading) have been conducted under a frame of “Molecules-to-Materials” approach.